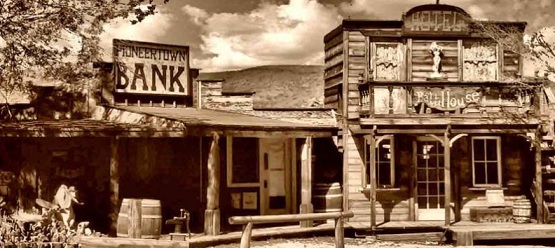

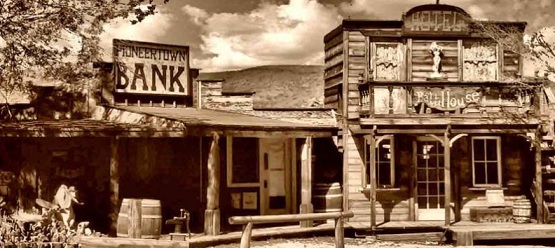

When you watch the old Westerns like ‘3-10 To Yuma’ you are usually treated to a Main Street with old-time businesses and homes on it. Horse drawn wagons lumber by. Victorian dress is on full display. A child taps an iron barrel ring down the dusty street with a stick. There’s the obligatory livery station, bank, gunsmith and hardware store, and cobbler. They all sport a nice tall false front, as the turn of the Century buildings often did. It’s exactly like “real life” in 1880.

But what you don’t see is the backs of those buildings. The Hollywood cameraman never goes back there. Guess what? There’s nothing back there! The buildings are literally just false fronts. You couldn’t actually live in one of those houses or do business in one of those stores. Sure, there are a few sets where you see characters going into and out of those businesses, but those movie sets may be in a completely different sound stage. Nothing is as it seems; it’s all staged for the camera.

Got your attention? Now consider how this happens in engineering…

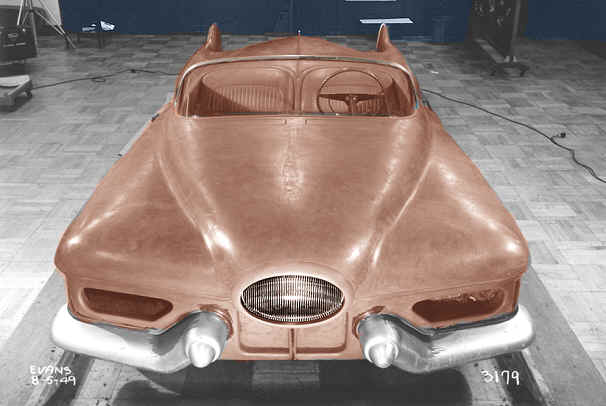

In engineering, we build prototypes to help people see what a finished product will look like. What people? Customers, potential investors, buyers, company executives, project stakeholders. Everyone needs an idea what a product will look like when the engineering is complete. It gets everyone on the same page, and dispels misunderstandings. Sure, the prototypes have a few warts. It can have reduced functionality, but it must *look* like the finished product, and must allow the sales force to tell the story and make the sale.

The problem with these prototypes is that they have almost none of the proper engineering – much like a Western movie set. Sure, they look good, and may even appear to work. For the purposes of a First Look, they satisfy everyone curiosity and need to see something tangible, and they get everyone thinking in the same vein. But they may not have any of the correct functionality! That fact alone leads to a false sense of completion.

Project managers, engineers, project stakeholders, and everyone alike can be lulled into a false belief that these systems are just a step away from completion. In actuality, they are like false front Western movie sets. You could never consider actually using them for everyday purposes. But after looking at them for an extended period of time, you come to a false belief that you could. You forget how far they are from reality.

It’s that “one step to final product” illusion that gets everyone into trouble — especially the engineers. They are the ones tasked with readying the product for release. Everyone around them believes the product is almost there – almost finished. But it’s not. The stakeholders have big money riding on a swift move from prototype to production. Customer expectations have been set, and they are waiting – sometimes not so patiently. Problem is, there is no swift move. The prototype must be thrown away and the “real” engineering begins. It’s like throwing away the Hollywood false front hardware store and building a real one. You can’t just build onto the false cardboard buildings. They have none of the real factors that go into a real building. Real hardware stores are expensive! And they take a long time to build! They are nothing like the quickie cardboard movie sets.

�